Welcome back to our series FSHN Research Journeys, which follows the research of graduate students in the Food Science and Human Nutrition program at The University of Florida. Today’s guest is Rose Omidvar, a first-year graduate student pursuing her Ph.D. in food science. Rose is studying the potential and process of developing cell-based seafood in the lab of Dr. Razieh Farzad.

Welcome back to our series FSHN Research Journeys, which follows the research of graduate students in the Food Science and Human Nutrition program at The University of Florida. Today’s guest is Rose Omidvar, a first-year graduate student pursuing her Ph.D. in food science. Rose is studying the potential and process of developing cell-based seafood in the lab of Dr. Razieh Farzad.

In this article, learn about how she is building her project from the ground up while fulfilling her longtime dream of combining chemical engineering with food science.

Rose:

Imagine going to a grocery store to buy your favorite fish filet, but you can’t find it. In another store, the fish is extremely expensive. Yet another store has fish on sale, but it doesn’t look fresh. There is one last store you’ve never been to, but you decide to give it a shot.

This store has the fish filet you want—but it is a cell-based fish. The label on it states this fish was grown from fish muscle cells and contains no mercury or micro-plastic particles. It has the same nutritional profile as your favorite fish, and it’s affordable. Which fish would you choose?

Why Do We Need Seafood Alternatives?

This scenario may sound like a movie script, but cell-based seafood is moving closer to reality. Along with increasing urbanization and the rise in the global population, the demand for fish is also growing. According to a report by the Food and Agriculture Organization of the United Nations, the world population is estimated to reach 9 billion by 2050.1 Unfortunately, over the past 40 years, 33.1% of the worldwide fisheries stocks have been depleted due to overfishing.2 Capture fisheries face an immense challenge as they navigate whether they can fulfill the growing demand to feed the global population.

A solution to this problem may be found in the lab. While Atlantic bluefin tuna takes three to five years to grow3 and Atlantic salmon takes more than two years to mature4, it takes days for cultured seafood cells to develop and mature until the product is ready for consumption.2 Thus, cell-based seafood production might provide a promising approach to alleviate the pressure on the marine ecosystem and aquaculture and provide a more sustainable food supply.

My Journey to Cellular Agriculture

I was born in Iran in a family of engineers. Seeing my parents’ successes motivated me to become an engineer as well. Growing up, I also developed a passion for chemistry and biology. When I entered college, I decided to study chemical engineering with a minor in food science because there are many overlaps between the two areas. For example, chemical engineers and food scientists work together in food processing, texture enhancement, food packaging, and more.

In 2017, I came to the United States and attended Florida State University to get my master’s degree in chemical engineering. With a passion for the food industry and plans to make a career in this field, I decided to obtain a Ph.D. in food science and joined the Gator Family in 2022. I joined Dr. Razieh Farzad’s lab because of her research in alternative seafood production. While in lockdown due to the COVID-19 pandemic, I had the opportunity to indulge in my favorite leisure activity: watching food documentaries. Those programs helped me realize that sustainability is a significant challenge in the food industry.

One particular show reported on the seafood industry, and after watching it, I discovered how limited our seafood resources are, with some fish species being endangered. This realization, along with some personal experiences, motivated me to contribute to the development of the seafood industry.

Steps Toward Making Cell-based Seafood a Reality

Aquaculture encompasses a growing industry and has been used widely around the world to address shortages in capture fisheries and stock depletion. Even though aquaculture is predicted to double its output by 2050, challenges exist due to ecosystem constraints such as climate change, algae bloom, and the need for land.5 Cellular agriculture, on the other hand, can significantly reduce water consumption as compared with aquaculture, lower the chance of foodborne illnesses, and provide a contaminant-free product with the possibility of altering its functional value and nutritional profile.6

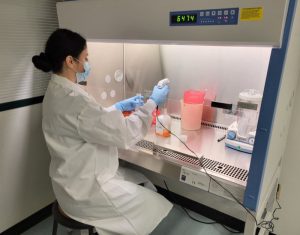

My research focus will be on how to grow fish filets from fish muscle cells in the lab using tissue engineering techniques under controlled culture and physiological conditions. This research requires knowledge of muscle cell isolation, the design of a proper environment to help cells to live and develop, and crafting scaffolds for the cells to grow on.

The Process of Growing Fish

To grow our product, we will first isolate muscle cells through biopsy from euthanized fish. Depending on the cell type, we will formulate the growth medium to supply the cells with nutrients such as amino acids, lipids, and sugars, as well as the correct ratios of growth factors and hormones. These cells are further grown in a bioreactor to scale up the production.

Next, 3D biomaterial scaffolds consisting of a porous material and providing mechanical support are then introduced to grow these cells into larger tissues that mimic the actual shape of a fish fillet.7 The goal is to come up with a product that can meet the demand for fish, recreate conventional fish sensory qualities such as smell, texture, and taste as well as visual appearance, provide nutritional value, and be contaminant-free and cost-effective.

It’s been reported that the willingness to pay for cultured products is linked to sex, age, views of other food technologies, and attitudes toward the environment and agriculture.9 To evaluate consumers’ willingness to purchase cell-based seafood, our lab is conducting a consumer acceptability survey among varied populations.

Key Technical and Regulatory Challenges in Making Cell-Based Fish

With growing interest in sustainable food consumption over the past few years, research into alternative meats has also increased.10 However, most of the cell-based studies have been performed on mammalians.7 As of now, there are no commercially available cell-based seafood products, and most of the research is considered the intellectual property of private companies.10 Therefore, I will start my research from ground zero. I anticipate a few hurdles ahead.

One of the challenges in this process is access to cell lines. There are a limited number of well-established in vitro fish muscle cell lines available.7 To address this shortage, I will investigate the cultivation of cell lines of tilapia in the lab rather than trying to source it from outside facilities.

Upscaling cell-based fish production to a commercial scale is another major challenge.7 A strong knowledge of bioreactor design is needed to balance the ratio of the components. Also, the scaffold must be designed in a way that enables cellular activity and transportation of oxygen and nutrients through the tissue while also being large-scale and cost-effective.10 I am looking to apply my chemical engineering knowledge in designing the reactor and calculating the ratio of the material needed.

Starting with Lean Fish and Looking to the Future

Another challenge is coculturing fat and muscle cells because of their different growth rates.2 For now, my focus will be on tilapia, which is in the category of lean fish. Lean fish usually has a lipid content of 0.1 to 1 percent. Due to the small amount of fat, there is less variation in the flavor profiles of lean fish. With the current limited knowledge of cell-based fish production, it is more feasible to base our research on less complicated processes involving lean fish and then explore the production of fatty fish. Finally, the U.S. Food and Drug Administration must approve cell-based seafood products for public consumption before they can be sold to consumers.

Challenges are a part of research, and I believe there is beauty in overcoming them. I wish to face the unknown and walk down a path nobody has ever walked, with the hope of creating a healthier and more sustainable society. One day, it would be fascinating to walk down the aisle of a grocery store and see the public enjoying a product I spent years developing—such as cell-based fish.

Rose Omidvar is a first-year Ph.D. student in food science. She is conducting research under the mentorship of Dr. Razieh Farzad. Rose’s favorite hobby is baking, and she has a part-time job where she makes baked goods. When she retires, she hopes to open a science-based bakery where products are customizable per the customer’s request to meet their dietary needs so even a person with diabetes can enjoy a piece of brownie as much as others.

References

- Food and Agriculture Organization (FAO). The State of World Fisheries and Aquaculture; FAO Fisheries and Aquaculture Department: Rome, Italy, 2018; ISBN 978-92-5-130562-1

- Porter, B. A., & Mueller, T. (2020). The zebrafish amygdaloid complex–functional ground plan, molecular delineation, and everted topology. Frontiers in neuroscience, 14, 608.

- https://oceana.org/marine-life/atlantic-bluefin-tuna/

- Salmon Life Cycle | Marine Institute

- Naylor, R. L., Hardy, R. W., Buschmann, A. H., Bush, S. R., Cao, L., Klinger, D. H., … & Troell, M. (2021). A 20-year retrospective review of global aquaculture. Nature, 591(7851), 551-563.

- Bhat, Z. F., Bhat, H., & Kumar, S. (2020). Cultured meat—A humane meat production system. In Principles of tissue engineering(pp. 1369-1388). Academic Press.

- Rubio, N., Datar, I., Stachura, D., Kaplan, D., & Krueger, K. (2019). Cell-based fish: a novel approach to seafood production and an opportunity for cellular agriculture. Frontiers in Sustainable Food Systems, 3, 43.

- MacQueen, L. A., Alver, C. G., Chantre, C. O., Ahn, S., Cera, L., Gonzalez, G. M., … & Parker, K. K. (2019). Muscle tissue engineering in fibrous gelatin: implications for meat analogs. NPJ science of food, 3(1), 1-12.

- Slade P. If you build it, will they eat it? Consumer preferences for plant-based and cultured meat burgers. Appetite. (2018) Jun 1;125:428-437. doi: 10.1016/j.appet.2018.02.030. Epub 2018 Mar 5. PMID: 29501683.

- Pajčin, I., Knežić, T., Savic Azoulay, I., Vlajkov, V., Djisalov, M., Janjušević, L., … & Gadjanski, I. (2022). Bioengineering outlook on cultivated meat production. Micromachines, 13(3), 402.

Looking for more posts exploring graduate research projects in the FSHN Department at the University of Florida?

Dive into the Research Journeys of other graduate students below.

M.S. Food Science

M.S. Nutritional Sciences

Ph.D. Food Science

Ph.D. Nutritional Sciences

4

4