Egg quality is determined by many things. Knowing the parameters used for determining egg quality increases your understanding of the process.

Eggs are widely used as a nutrient source. People get their eggs from many different places: the grocery store, a local vendor, or from their own flock. No matter the source, the issues that denote quality in eggs are nearly universal. It is important, as a consumer, to be able to identify these quality parameters and how changes in them may impact the quality of eggs. It is also important to note that quality and safety do not mean the same thing in this regard.

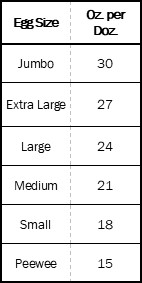

Most eggs purchased from retailers are graded for both interior and exterior quality, along with size. Generally, you will see the “Grade A” designation along with a size (Jumbo, Extra Large, Large, Medium, Small, and Pee Wee). Occasionally, you may see eggs designated as “Grade AA”, but this is very rare in the retail market. Additionally, you may see a “Grade B” designation at the retail market, but this is also very rare. Most eggs for sale in the United States that have been graded to USDA standards are “Grade A”. If you would like additional information about egg grading, please click here or here.

In Florida, ungraded eggs can be sold directly to consumers under the Limited Poultry and Egg Operation permit. An article containing information about the Limited Poultry and Egg Operation can be found here.

Grading eggs relies on determining both interior and exterior characteristics. Let’s take a look at why an egg might not make the “Grade”.

Major Egg Quality Issues

Dirty Eggs

Dirty eggs possess visible marks of contamination, either by foreign material or feces. Commercial eggs are almost always washed before packaging. This process cleans dirty eggs and helps to sanitize them. Eggs that cannot be cleaned completely are either downgraded to a “Grade B” or not sold for human consumption. Eggs that are deemed not fit for human consumption can be used in other processes such as pet food.

Misshapen Eggs or Shell Defects

Eggs are supposed to be shaped, well, like eggs. However, sometimes hens lay eggs that do not conform to the traditional egg shape. Misshapen eggs do not automatically pose a safety risk, but they are usually downgraded to a “Grade B” because consumers won’t buy them. Also, misshaped eggs do not fit into the cartons or flats very well. Eggs that possess other cosmetic issues are also downgraded. This includes eggs with pimpled or rough shells or eggs with “body checks”. A “body check” occurs when the egg shell cracks slightly while the egg is still inside the hen. The hen adds additional layers of shell to the spot, and there is no safety issue. Most “body check” eggs are not detected unless candled.

Interior Quality Issues

Interior quality issues that downgrade eggs typically have to do with yolk or albumen quality. Disease within the flock is a major cause of downgrades and loss of interior quality. It is important to note that albumen quality decreases as the hen ages, so older hens will, typically, have a lower albumen quality than younger hens. Flattened yolks are another issue affecting interior quality. Yolk quality decreases over time after oviposition; so the age of the egg is an important factor for this quality issue. Rubbery yolks are caused by the freezing of fresh eggs or by diet issues such as the use of cottonseed oil or velvetleaf seed in the ration.

Other Egg Quality Issues

Yolk Color

Yolk color varies in eggs because the color of the yolk depends on the type and amount of plant pigments ingested by the hen. Xanthophylls are the most common type of pigment that impart color to both the yolk and the chicken skin. Using white corn or other low pigmented plants in the hens’ diet will cause the yolk to be a paler yellow. Conversely, a poultry diet that contains very yellow corn, marigold extract, and even grasses will cause a more intense yellow in the yolk. It is important to understand that these variances in yolk color do not correlate (either positively or negatively) with the nutritional qualities of the egg or safety.

It is sometimes reported that the yolks of hard-cooked eggs may have a greenish colored ring around the yolk. This is caused by one of two issues: 1) the egg has been overcooked, thus causing the iron and sulfur in the yolk to display this greenish color, or 2) there is an abundance of iron and sulfur in the water that is consumed by the hens. The abundance of these two elements in the yolk cause the greenish tint. In each of these cases, the green ring does not pose a safety issue; it is purely cosmetic.

Air Cell Size

All eggs have an air cell, usually located at the large end of the egg. The air cell is used for gas exchange while the chick is developing in the egg. Over time (even in unfertilized, un-incubated eggs) the air cell will get larger. It is because of this increase in size over time that fresh eggs will tend to sink in water, while older eggs will float. During candling, eggs with larger air cells are downgraded. This is why older eggs are not able to be graded a “AA”.

Blood & Meat Spots

Candling of eggs allows us to look at the size of the air cell. It also allows us to look for blood spots and/or meat spots in the eggs. Commercial egg producers remove all blood spot and meat spot eggs that are found. However, they can be found in eggs that do not undergo the commercial grading process.

Blood Spots

Many yolks develop in the ovary of the hen simultaneously. Since hens typically lay one egg per day, there is a progression of development in the ovary. These unreleased yolks are held in the ovary in small sacs lined with blood vessels. These blood vessels bring the nutrients to the developing yolk. During ovulation, the sac splits open and drops the yolk into the infundibulum, which is at the top of the reproductive tract. In most cases, the space where the sac splits open (the stigma) is devoid of any blood vessels. In some cases a vessel crosses the stigma and a drop of blood deposits on the yolk. The result of this is a blood spot. These spots do not pose a safety risk. Blood spot eggs are removed from commercial production because of aesthetic reasons. Blood spots are removed using the tip of a knife or the tine of a fork when the egg is broken out.

Meat Spots

Meat spots are another aesthetic defect found in a small number of eggs. Like blood spot eggs, meat spot eggs are removed from commercial consumer production when found, so it is unlikely that you will find one from store-bought eggs. Also like blood spots, meat spots do not pose a safety risk and can be removed from the egg with the tip of a knife or the tine of a fork. Unlike blood spots, meat spots are typically found in the albumen (white) of the egg. Meat spots occur when a small piece of the reproductive tract sloughs off during egg formation.

Chalazae

The chalazae are the thick strands of albumen that are found close to the yolk of the egg. Very thick chalazae can be mistaken for meat spots or even a developing embryo when candling. An old saying is that the chalazae are the sperm from the rooster that has become trapped in the egg. In reality, the chalazae are just really thick strands of albumen. They function to keep the yolk centered within the egg as it is being turned by the hen during incubation. The chalazae are a vital part of the egg and are not considered a defect.

SUMMARY

Eggs are a good source of nutrition and most of the quality issues that have been discussed here are not seen in commercial eggs. Remember that the defects described above are quality defects and will cause an egg to be downgraded or not used at all in a commercial setting. However, quality and safety are not the same thing, and the defects described above do not (usually) cause any concern for food safety. If you procure your eggs from your own flock or from a non-graded source, you may find a quality defect or two, so keep the information above in mind when purchasing your eggs.

2

2